Electromechanical test axes

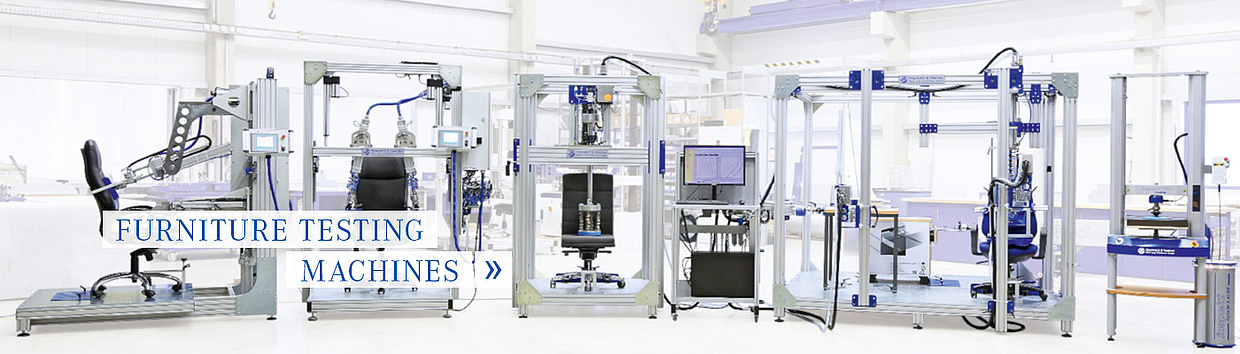

Test axes for furniture testing, component testing and material testing

Electromechanical test axes can be used to perform fatigue tests, operational strength tests, functional tests and also static tensile tests, compression tests, bending tests and peel tests. The field of application of these test axes is very versatile and covers the areas of furniture testing, component testing and material testing.

Advantages:

- High control precision

- Variable stroke and load level

- Low noise

- Modular and flexible test systems - "from the single test rig to the all-rounder"

- Easy integration and variable arrangement in test fields - great flexibility in test set-up and test sequence in combination with our test software

- Standard-compliant testing according to DIN EN ISO, BIFMA, BS, NEN, GB or individual test sequences can be set up (test templates)

Technical possibilities:

- Loads up to 20 kN

- Strokes up to 500 mm stroke with spindle drive (other parameters on request)

Test Software:

With the help of the testing software, it is possible to define movement sequences widely freely. This also includes switching between different speeds during the movement and reacting to events, such as reaching defined positions or forces, time marks, etc. For this purpose, specific programme blocks are processed one after the other. These can in turn be called up cyclically.

The test data can be evaluated internally, logged or exported. In addition, test sequences and test results are securely stored and managed in the SQL database.

A convenient search function allows quick finding and compiling as well as statistical evaluation of different tests. Thus, statistics and complaints can be easily processed.

Further advantages of coupling to testing Software:

- Single-axis and multi-axis tests; Simple and complex test sequences - without programming knowledge

- Integration of external sensors as measured or controlled variables (temperature or noise level sensors, light barriers, etc.

- Connection to Outlook, e.g. as monitoring of the test sequence with e-mail in case of test Abort