Testing technology for seats and seat rows in rail vehicles

Test rigs for functional tests, fatigue tests, durability tests

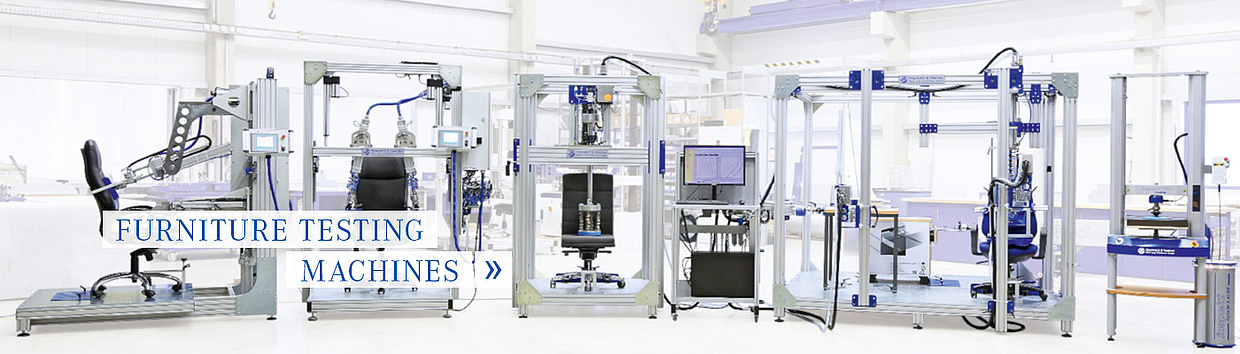

The furniture and component testing technology from Hegewald & Peschke is versatile. Especially for the testing of seats and seat rows in rail vehicles, various test procedures can be carried out with the test fields and test rigs.

Universal test field for railway seats

- Equipped with pneumatic or electromotive test axes and various load pads for force application

- Flexible arrangement of the test axes

- in height (height-adjustable transverse profiles)

- in width (horizontally freely positionable holders)

- in depth (roller guide)

- Tensile and compressive load possible

- Test angle infinitely adjustable via swivelling bearings

Wide range of testing possibilities

- Backrest testing (with pneumatic actuator for operating adjustment switches for the backrest)

- Armrest testing (Load application straight or at a certain angle)

- Seat testing

- Testing of the tables on railway seats

Software-based control with Calmar Pro

- Decentralised, modular control concept for test configurations with up to 5 axes

- Test axes can be operated separately or flexibly combined for test procedures

- Processing of tests on the basis of test templates (standard-compliant or customer-specific)

- Free parameterisation of test sequences

- Customer-specific characteristics / results / test sequences

- Test report

- Online visualisation (real-time graphics/values)

Test field for swivel tests on seat modules with 1 to 3 seats

- Durability and fatigue test

- by cyclically rotating the seats horizontally back and forth by 180 degrees

- by continuous rotation in one direction

- Speed of the swivel test 15 rpm

- Customised design of the protective enclosures

- Rotary drive mounted centrally above the test specimen

- Adjustable drive arms that can be set to the width of the test specimen

- Transfer of the rotary movement via the backrest

- Pneumatic actuator for releasing the seat rotation function

- Control and monitoring of the actuator integrated in the PLC control system

- Switching status serves as a precondition for the next test step

Convenient and intuitive control via PLC with touch screen

- Input of the test parameters via the touch-panel:

- Number of cycles

- Angle of rotation

- Test speed

Pendulum impact test on seat backrests

- Testing of the backrests of seats with regard to vibration behaviour and stability according to corresponding standard

- Impact force is transmitted to a load cell mounted on the rear of the hammer

- Adjustment of different reaction forces possible

- Manually height-adjustable cross-beam for fastening the impact device

- Optional: measurement of the impact force via movable front plate on the impact hammer

Test rig for drop tests according to EN 1728

The drop tester can be used universally for drop test or drop impact tests according to EN 1728, EN 581-2, BIFMA X5.1, BIFMA X 5.5, BIFMA X6.1, DIN4551, DIN 4573, EN 14072, NF DF61-062 or according to QC/T 805-2008 and TB/T2961-1999

- Drop tests with weights from 9.1 kg to 200 kg

- Height and width of test specimens variable

- Max. test specimen height: 1850 mm - drop height

- Comfortable and intuitive control via PLC with touch screen

- Expandable with an acceleration sensor for testing according to RAL GZ430/4.

Advantages

- Drop cycles adjustable

- Monitoring of ageing

- Optional setting of a constant drop height relative to the test specimen surface or a fixed drop position

- Definable drop zone and tolerance for the adaption of the drop shaft