Search Results

Component testing on steel and aluminium for the automotive industry

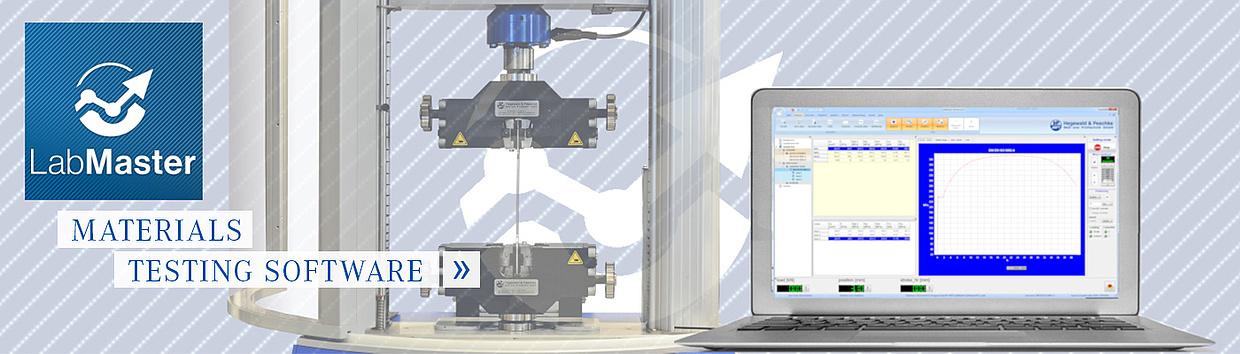

Universal testing machine inspekt 250kN

The application area of the universal testing machine inspekt 250kN covers metal tensile tests on round aluminium specimen complying with DIN EN ISO 6892 as well as special component tests. These include e.g. squeezing tests on automotive parts and assemblies for the determination of breaking loads or limit loads.

For this purpose, the universal testing machine is equipped with a second load cell as well as an automatic long distance extensometer. This ensures maximum resolution also in the lower load area of the testing machine.