Search Results

Determination of mechanical properties on CFRP samples

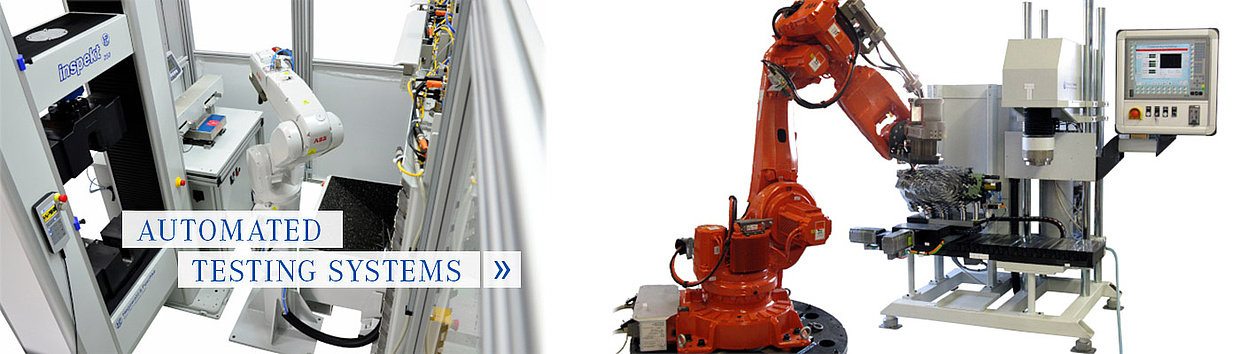

Universal testing machine Inspekt 250kN with temperature chamber and video extensometer

Carbon fibre reinforced plastics (CFRP), commonly referred to as carbon, are manufactured by embedding carbon fibres as reinforcement into a plastic matrix. This structure ensures high strength and rigidity accompanied by low weight; the material is therefore used, for example, in aeronautics, vehicle construction or for sports equipment.

However, the material properties exhibit strong directional dependence. Both, strength and rigidity are significantly higher in the direction of the fibre compared to perpendicular to the main fibre direction. It is therefore important for the complete assessment of the material properties to subject the samples to loads in different directions, depending on the area of application.

Using different test tools, the universal testing machine Inspekt 250 kN allows performing tensile tests (see Fig. 1), bending tests (see Fig. 2) as well as bulging tests on CFRP samples. Bending tests on CFRP samples become also relevant if the material exhibits very high rigidity, and tensile tests for the determination of the relevant characteristic values are therefore not suitable.

Likewise, the material properties of carbon fibre plastic composites are impacted by the ambient temperature. Because these materials are subject to considerable temperature fluctuation in many areas of application, such as aeronautics or vehicle construction, tests under these conditions are very important. The adaptation of a temperature chamber in the testing compartment allows applying the different types of strain (tensile, pressure, bending) in a temperature range from -70 °C to +350 °C.

By using a video extensometer (see Fig. 3), the longitudinal extension of the CFRP sample can be determined both inside and outside of the temperature chamber. The advantage of an optical extension measuring device lies in the non-contacting measuring principle. The brittle fracturing behaviour of many carbon fibre reinforced plastics cannot cause damage to the measuring system.

Optimal sample clamping is achieved by using hydraulic clamping devices. All test tools are dimensioned up to the nominal load of the testing machine of 250 kN. This allows covering a large range of different tests in a flexible manner.

| Fig. 3: Video extensometer | Fig. 4: Fracture of a CFRP sample |