Search Results

Determination of the abrasion and friction properties on deep-drawn sheets

Special testing machines for strip tensile tests, friction tests and draw-bead tests

Sheet metal forming test methods provide characteristic values for metal processing. One sheet metal forming process is deep drawing. In the automotive industry, the demands on the properties of sheet metal are constantly increasing: these include, for example, high stability with simultaneous formability and the lightest possible weight.

Application:

Possible types of tests:

- Tensile tests on the strip

- Friction tests

- Tribological tests

- Draw-bead tests

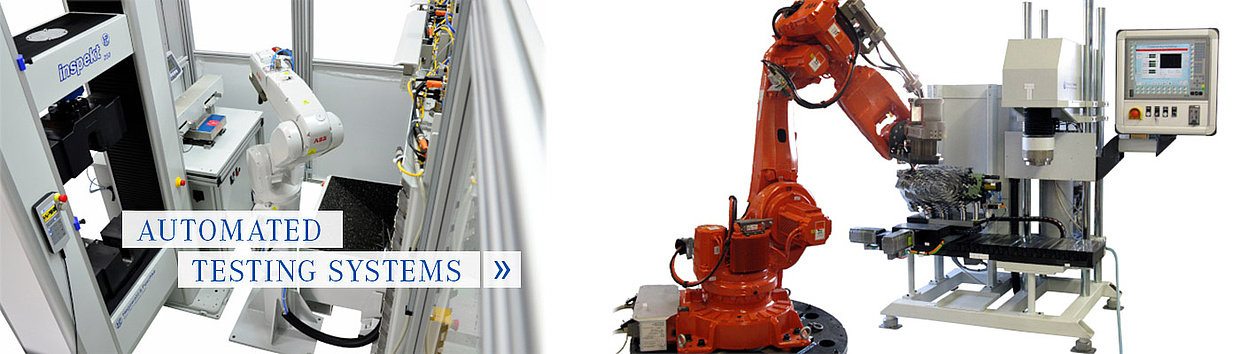

These special testing machines can be used to determine the abrasion and friction properties of deep-drawn sheets. Such sheets are used, for example, for engine hoods, fenders, doors or pillars. Automobile manufacturers produce body parts like these by automated deep drawing.

General features:

- Regulation of the tensile load and test speed

- Regulation and recording of the holding force

- Control of specimen temperature regulation in the grips and optionally separate specimen pre-temperature regulation below the grips

Draw-Bead-Tests

In order to control the material flow so that the sheet does not crumple or even tear locally during forming, so-called draw beads are incorporated on the drawing edges of the forming tool. They act as brakes and prevent excessive local material flow into the drawing mold. These draw beads are the neuralgic points in the drawing process. They only fulfill their function if optimum friction conditions prevail between them and the sheet. These friction conditions are set by lubricants or coating of the body sheet during production. Galvanized sheet metal has inherent sliding properties that are used during drawing. The measure of friction is the coefficient of friction. It must be determined in order to select the right lubricant or the right coating for a particular sheet. The test method for this is the draw bead test (DBT), in which a sheet specimen is drawn at a defined force and speed through a clamping device equipped with a drawing bead.

Friction tests

By replacing the DBT clamping device with plain clamping jaws without a drawing bead in just a few steps, friction force tests can also be carried out. These involve working with particularly high contact pressure and maximum pull-through speed. The tests are used to test the durability of surface coatings - for example the galvanizing already mentioned - as the forming must not cause any damage to the corrosion protection of the sheets.

High-precision, high-speed thermocouples integrated into the clamping jaws record their temperature change during the test, which is also a measure of the frictional force. Another extra concerns the design of the clamping jaws. Special ball-bearing stops on the edges of the jaws prevent the sheet specimens from deforming during the test due to slightly uneven contact pressure across the jaw cross-section.

Strip tensile tests

In order to carry out tensile tests on the strip, jaws with pyramid toothing, for example, are used, which in turn can be easily exchanged in the grips.

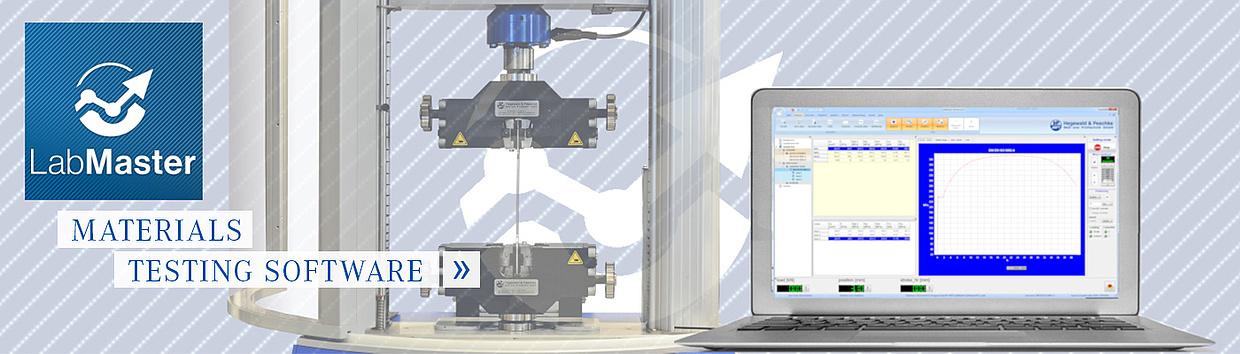

Test parameterization with LabMaster testing software

All relevant parameters for the different types of tests can be set in the H&P testing software LabMaster. Likewise, the regulation of the temperature of the clamping jaws as well as the clamping force is carried out in the software.