Search Results

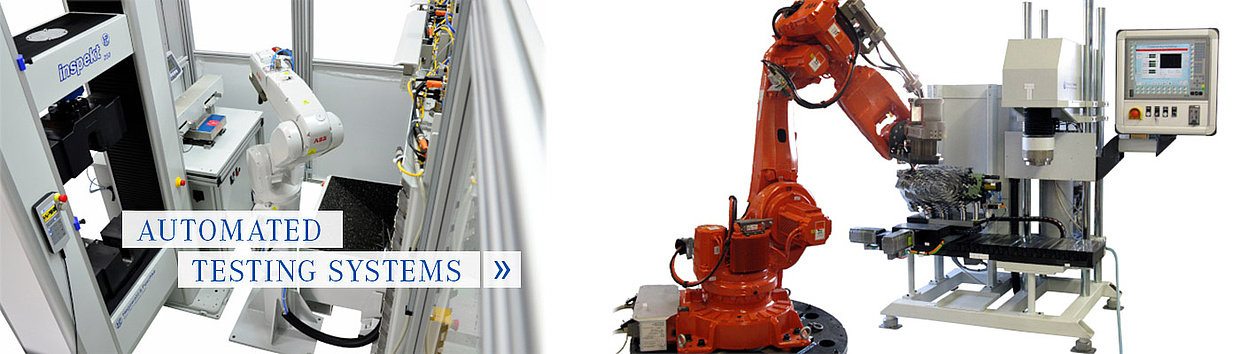

Fully-automated metal tensile test

Automated testing system with universal testing machine and robot

The automated test centre from Hegewald & Peschke offers high test speeds, operator-independent evaluation and automatic recording of test results. The heart of the system is a universal testing machine of the Inspekt type. All handling tasks required for the inspection process are performed by a fully automatic six-axis robot. The specimens pass through several stations in the test centre, where they are measured and marked, among other things, before being tested. The system processes a large number of different specimen shapes and dimensions, which is made possible by specially developed gripping systems for the robot arm, among other things. The measurement of the specimen in its initial state and, if necessary, also during the test is carried out contact-free via laser - wear-free and highly accurate.

The specimens are prepared in magazines specially tailored to the motor skills of the robot. A large number of specimens can be stored in them for testing, even in different versions. If required, the testing system works fully automatically and without manual intervention in 24-hour operation. As a rule, the testing machine is equipped with double-sided hydraulic clamping devices. They guarantee exact positioning of the specimens because they can be approached evenly from both sides. Optical sensors monitor the clamping process and prevent misalignments. The test results are automatically transferred to a host computer and can be managed directly by an ERP system.