Search Results

Mechanical specimen grips

Gripping, clamping, holding - from rough to fragile

Hegewald & Peschke offers a wide range of mechanical grips for tensile tests. This includes both from-fit and force-fit grips, each of which can be used for a wide range of materials, specimen shapes and temperature ranges.

Force-fit grips:

Vice Grips

- External tensioning

- Field of application: Up to 20 kN, polymers (thermoplastic, duroplastic), foils, food,

Advantages:

- Light

- Symmetrical and asymmetrical clamping

- Adjustable clamping force

Disadvantages:

- Only for small forces

- Difficult to reach reproducable clamping forces

- Clamping force decreases during testing

Princer Grips

- Self-tensioning

- Field of application: Up to 20 kN, elastomers, plastics, textiles

Advantages:

- Light

- Clamping force increases during testing

Disadvantages:

- Only symmetrical clamping possible

- Clamping and pre-clamping force cannot be adjusted

Wedge type Grips

- Self-tensioning

- Field of application: Up to 600 kN, metals

Advantages:

- Up to high forces

- Clamping force increases during testing

Disadvantages:

- Heavy

- Only symmetrical clamping possible

- Clamping and pre-clamping force cannot be adjusted

- Spring back after brittle fracture

Screw type wedge action grips

- External tensioning

- Field of application: Up to 250 kN, metals

Advantages:

- Symmetrical and asymmetrical clamping

- Adjustable clamping force (Reproduceable clamping forces can be reached with a torque wrench)

- Up to high forces

- Frictional fixation after fracture

Disadvantages:

- Heavy

Form-fit grips

Specimen holder for shoulder, screw and thread head testing

- Field of application: Clamping of tensile specimens that cannot be gripped directly with clamping jaws due to their size, geometry or structure

- For example suitable for:

- Testing of thread specimen

- Testing of shoulder specimen

- Testing of screws

- Testing of tubes

- Testing of tapes

Further information:

Wedge type grips:

Screw type wedge action grips:

Screw type wedge action grip 10 kN

Screw type wedge action grips 20 kN and 50 kN

Screw type wedge action grips 100 kN and 250 kN

Clamping jaws for screw type wedge action grips 100 kN and 250 kN

Specimen holder:

Videos:

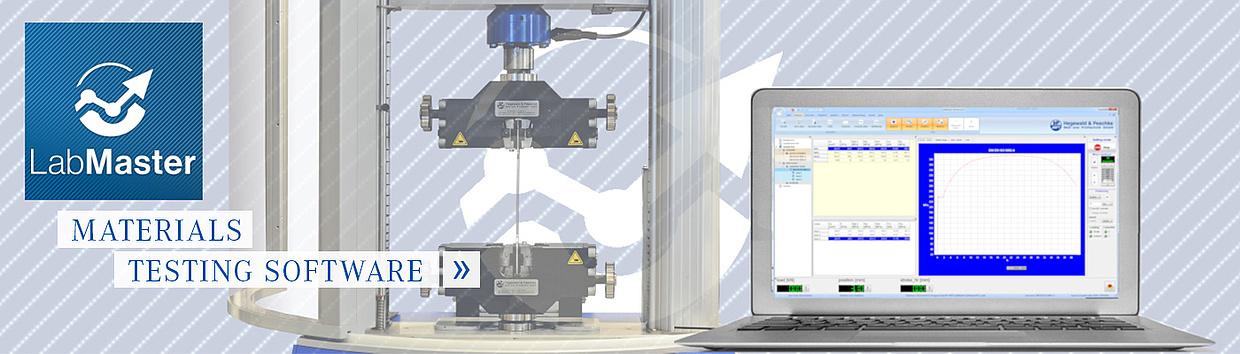

Metal tensile test according to EN ISO 6892-1 with screw type wedge action grip