Search Results

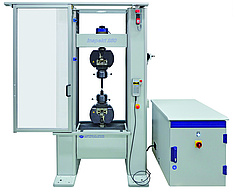

Universal testing machine inspekt

Material testing machines 100 kN to 2.500 kN

The universal testing machine inspekt offers high-class mechanic precision, frame stiffness and modern control electronics. Customers also profit from the convincing cost/performance ratio. The top-quality, rugged machines can be used for almost any testing task.

The size of the test room of the individual machines can be customized. It is also possible to add one or more test room.

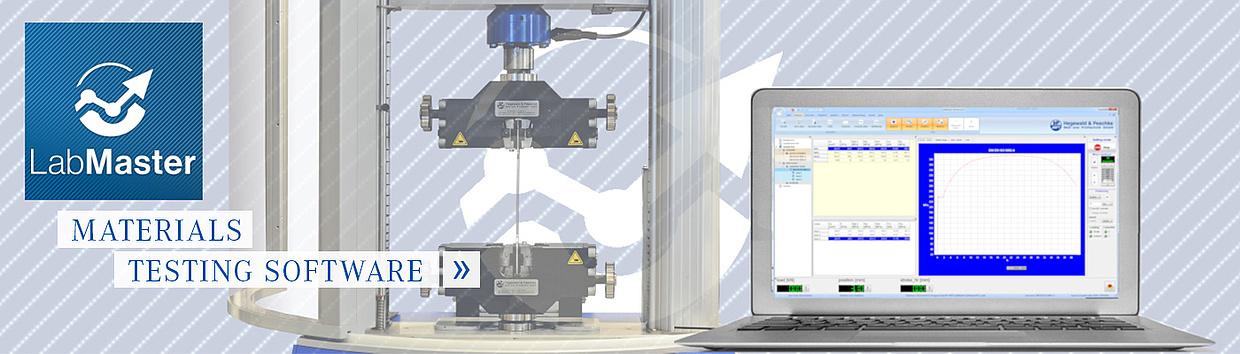

In combination with our user-friendly testing software LabMaster, standard-based and customer-specific tests can be easily implemented. Testing machine, testing software and our extensive range of accessories such as specimen grips and testing tools, extensometers or temperature control devices are optimally matched to each other and offer the ideal testing system for a wide variety of testing applications (tensile tests, compression tests, bending tests, peel tests,...).

Advantages and features of the universal testing machines inspekt table

Solid construction for highest measuring and control precision

- 4 guiding columns and 2 backlash-free precision ball screws

→ Precise force transmission

→ High lateral force stability

→ Increased axial stiffness - Robust design with casing and bellow cover

→ Low maintenance needs

→ Also for use in harsh production environments - Powerful brushless AC drive

→ Increased test speeds

→ For static material testing as well as for alternating and continuous loading

Flexible design for versatile applications

- In standard lower and upper test rooms; optional additional lateral test room

→ Different test tasks without changing the test tools

→ Ergonomic working height - Variable load frame for different test room heights and widths

- Connection of peripheral devices (e.g. ovens, temperature chambers) and additional measuring and control channels possible

Our testing machines speak your language: LabMaster - the testing software from Hegewald und Peschke

- User-friendly usage concept

- Complete software including all test modules (tensile, compression, bending, peel test) without additional costs

- Universally applicable: simple and complex test procedures: standard-compliant and customer-specific

- High flexibility for integration of external devices, data import and export as well as free configuration of test procedures

Innovative control electronics for maximum measurement resolution & extensive functionality

- High modularity and control precision

- Adaptive controller

- High-quality signal converters for maximum resolution

- Standard functions:

- Force, displacement, strain control

- Overload protection

- Automatic sensor identification incl. calibration data storage

- Specimen break detection

- Return function

- Manual positioning via hand panel or our testing software LabMaster

Highest safety with maximum operating convenience

- CE-compliant protective housing optionally available for every application

- Sustainable: capable for cost-efficient and application-oriented updates/upgrades

- Stable and vibration-damped: large machine feet allow leveling as well as installation without foundation and increase stability

Further information:

Product information testing machine inspekt 100 kN

Product information testing machine inspekt 150 kN

Product information testing machine inspekt 200 kN

Product information testing machine inspekt 250 kN

Product information testing machine inspekt 400 kN-1 (load frame 1)

Product information testing machine inspekt 400 kN (load frame 2)

Product information testing machine inspekt 600 kN

Product information testing machine inspekt 1200 kN

Product information testing machine inspekt 1500 kN

Current posts on the inspekt series:

Tensile testing on steel pipes

Testing the properties of rocks under the influence of temperature