Search Results

Testing of flat tensile samples for the automotive industry

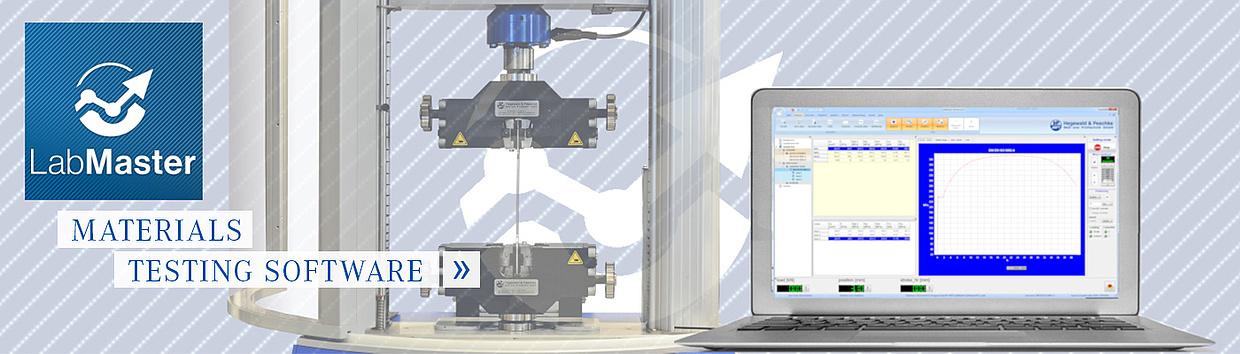

Universal testing machine inspekt 250 kN

With this universal testing machine inspekt 250kN flat tensile samples of aluminium, stainless steel and a variety of deep-drawn sheets can be tested, that are used in the automotive manufacturing. Furthermore, bending tests on sheet metal as well as bands of body components can be performed.

The universal testing machine is equipped with a hydraulic clamping fixture as well as a guard door.