Search Results

Testing on disc springs

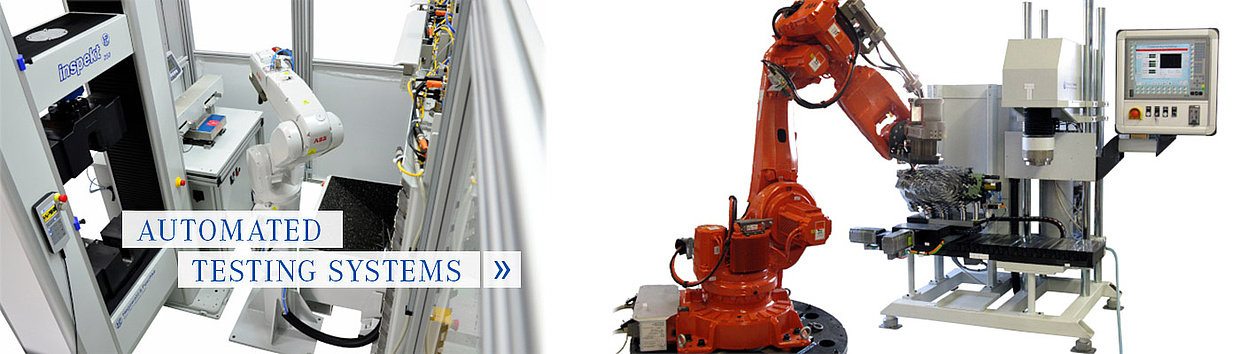

Universal testing machine inspekt 100kN

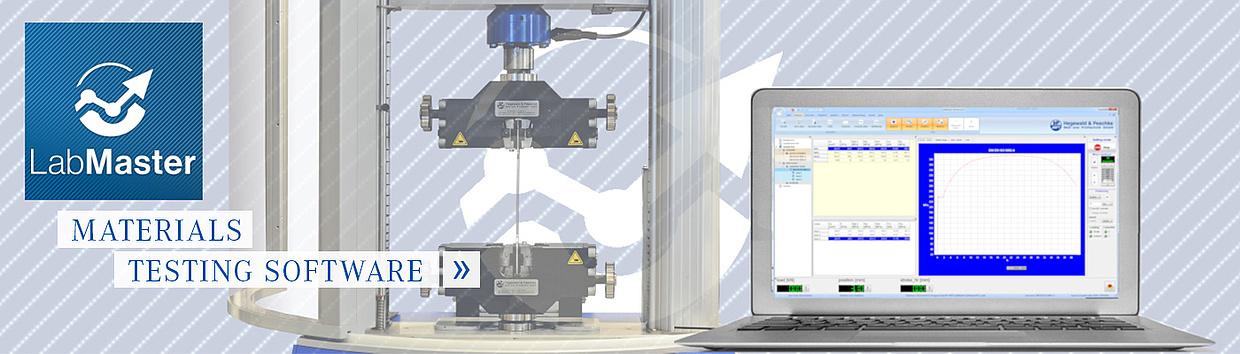

For this application the universal testing machine Inspekt 100kN is used as a disc spring testing machine. For this purpose it is equipped with a suitable testing device for disc springs. This testing device for clutch springs is equipped with a force measurement and a spring travel measuring system with a maximum test force of 100kN. The test is carried out and the results evaluated with the material testing software LabMaster.

Various testing possibilities:

1. testing of the actuation travel of the diaphragm spring:

- Measurement of the force and the spring travel

- Random non-destructive testing during production as part of quality assurance

2. checking the uniformity of the bending of the spring tongues by scanning with a measuring probe

Testable spring dimensions:

- Outer diameter: 270 to 440mm

- Inner diameter: 50 to 150mm.

The test device consists of:

- 3 load cells below the tool holder,

- upper thrust collar holder with block protection

- lower measuring platform with force measurement and adjustable holder for displacement measuring probes.