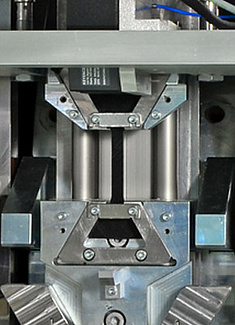

Rotational impact tester

for impact tests

The rotational impact tester is used for impact tests. These highly dynamic tensile tests with a long linear test path are applied, for example, in the testing of fibre composites and technical textiles.

With the rotational impact tester, strain rates of up to 350 s-1 can be achieved. Material parameters at such high strain rates are used for crash simulations, e.g. in lightweight construction or in the automotive industry. They represent the material behaviour at 50 km/h (14 m/s).

Compared to other testing devices for impact testing (e.g. pendulum impact testers, drop testers or high-speed testing machines), the rotational impact tester stands out due to its high testing speed and its high impact energy, at a comparatively small machine size. A detailed comparison of the different testing devices for impact testing is listed in this flyer.

Functionality:

In this rotational impact tester, a 300 kg rotating flywheel mass is decisive for the resulting speed and energy storage. This energy is transferred to a linear slide with integrated specimen holder for testing. The actual tensile test then only takes a few milliseconds. During this time, the physical measured variables force, displacement and time are recorded.The machine is operated in a user-friendly manner completely via a touch panel and the recorded measurement data is stored in a buffer memory. The values are then automatically imported into LabMaster and are available for individualised evaluation. LabMaster works on the basis of an SQL database and is also used for traceable measurement data backup.

Results:

- Strain rates

- Force-displacement diagrams

- Modulus of elasticity, tensile strength and elongation at break at defined strain rates

- The area below the force-displacement diagram represents the work performed and corresponds to the energy dissipated