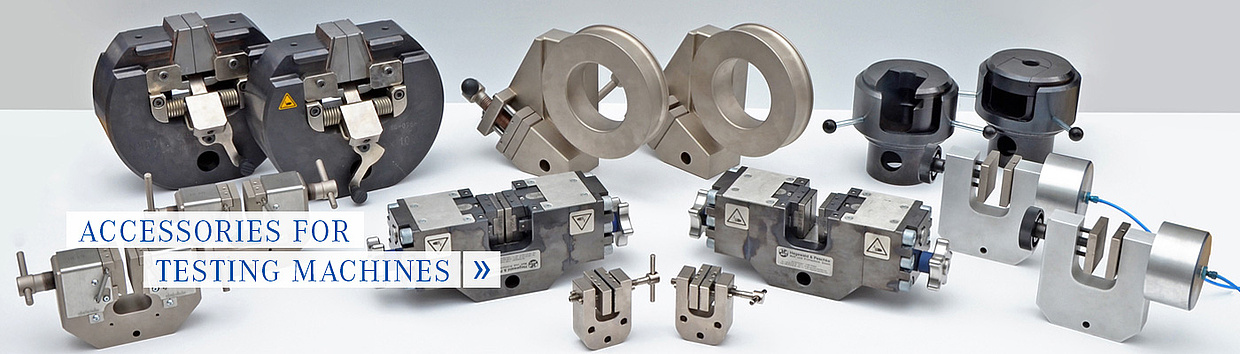

Accessories for Universal Testing Machines

The range of testing machine accessories is as comprehensive as the testing tasks are varied and individual. In order to equip your testing system according to its intended use, we have a comprehensive range of accessories for materials testing such as specimen grips and extensometers, but also temperature chambers, safety and changing devices. We present a selection of these on this page. If you are missing the desired testing accessories, please contact us. We will find the right solution for you.

Second-hand accessories for material testing

Current selection of second hand testing machines, hardness testing instruments and accessories

Show all

![[Translate to englisch:] Video extensometer ONE1 with testing machine](/fileadmin/_processed_/6/2/csm_15-012-600_Videoestensometer_ONE1_01_b171ef887f.jpg)

![[Translate to englisch:] Temperature chamber closed](/fileadmin/_processed_/5/3/csm_Kachelbild_Konditionierung_302ba095df.jpg)