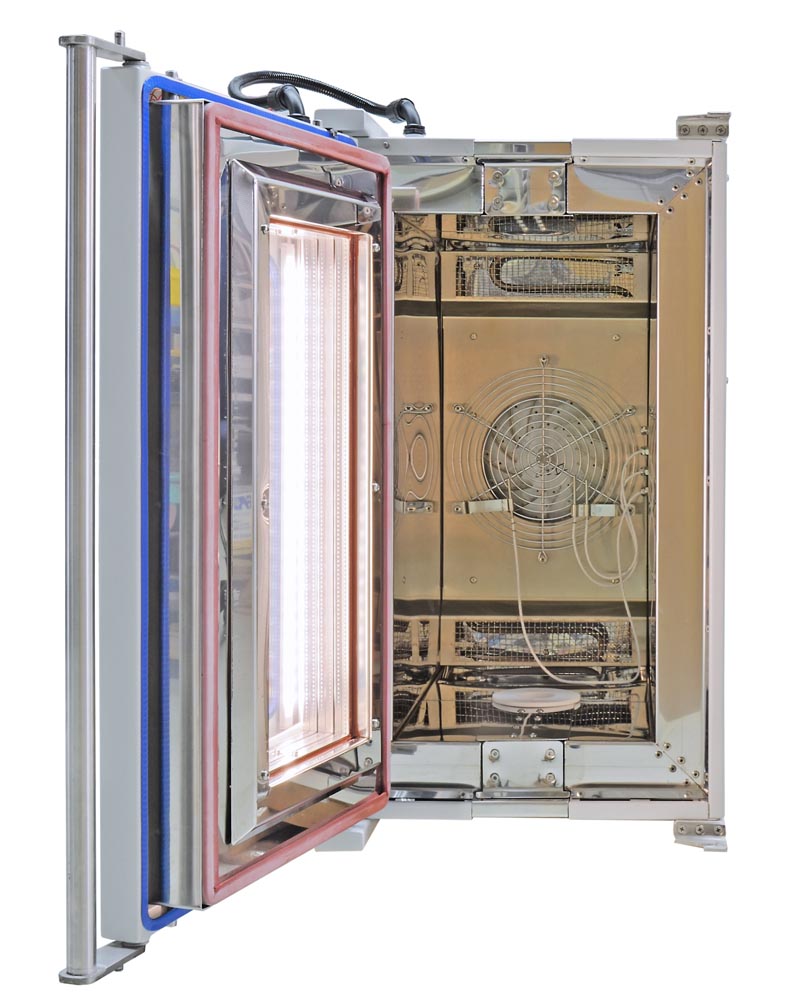

Temperature chambers and climate chambers

Temperature and climate chambers provide the possibility of material and component testing under defined environmental conditions. The simulation of temperature and humidity whilst applying distinctive loads to the specimen is of great importance in material research, developing new materials and also for industrial quality assessment.

The temperature chambers are used for material and component testing in a wide temperature range. The different standard dimensions of the temperature chambers ensure compatibility with our universal testing machines from the inspekt, inspekt table, inspekt duo and inspekt blue series and offer the right solution for different test methods and materials. The integration of the chambers into a testing system is realized either permanently via a holder with rail guide or flexibly with a trolley.

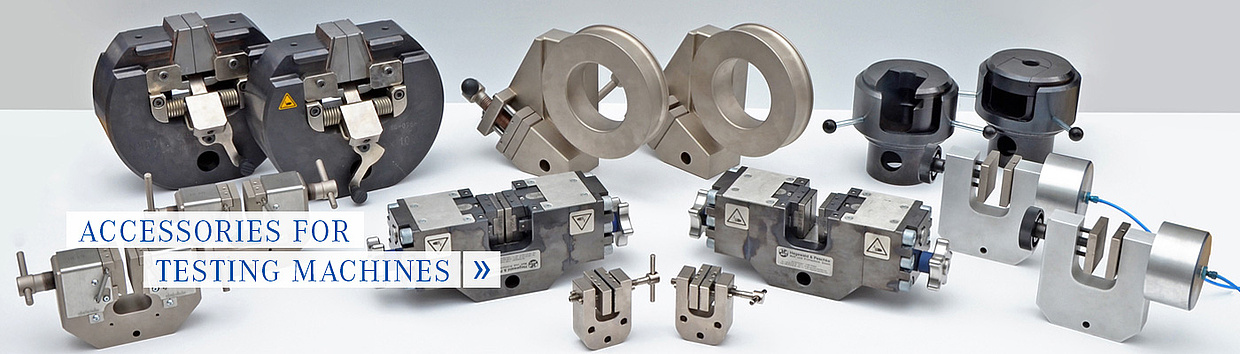

Hegewald & Peschke offers customized complete solutions for material testing under defined environmental conditions together with temperature chamber-compatible clamping fixtures and testing tools as well as the corresponding additional components for the load line.

Features and Advantages

- Direct status display in the door via LED-illuminated symbols

- Window with heated/cooled 5-fold glazing made of anti-reflective glass including indirect LED lighting

- Optimal viewing conditions for optical strain determination

- Ergonomic swivel lever handle over the entire chamber height

- Uniform temperature distribution throughout the entire heating chamber

- In standard: direct cooling by LN2

- Dust-protected radial fan

- 3 Thermocouples

- 1 Air temperature sensor

- 1 Movable specimen temperature sensor

→ Permanent display of both

→ Temperature control switchable between specimen and air temperature - 1 Sensor for overtemperature protection

- Frame with jacket cooling

- Improved safety by avoidance of high surface temperatures on the outside of the temperature chamber

- Lateral entry (ø50 mm) for clip-on extensometer or similar equipment

- Slide in inserts and compensating rings

- Moving the temperature chamber into and out of the test area without removing the fixtures/adapters

- Considerable reduction of the set-up times

- Compensating rings for thermal sealing at the feed-throughs of the load introduction rods into the temperature chamber

- Integrated controls

- Electronic digital controller (type Eurotherm) with simultaneous display of target and measurement temperature

Convenient control via LabMaster testing software - everything at a glance

- Temperature regulation on/off

- Switching between control of air or specimen temperature

- Test room illumination

- Display of the temperature in the test software

- Synchronization of mechanical and thermal stress (block program)

- Temperature programs (ramps, etc.)

- Up-to-date LAN/Ethernet connection

Second-hand accessories for material testing

Current selection of second hand testing machines, hardness testing instruments and accessories

Show all

![[Translate to englisch:] Anzeige der Temperierkammer in LabMaster](/fileadmin/_processed_/c/5/csm_Temperierkammer_Softwareeinbindung_e56dc1d635.png)