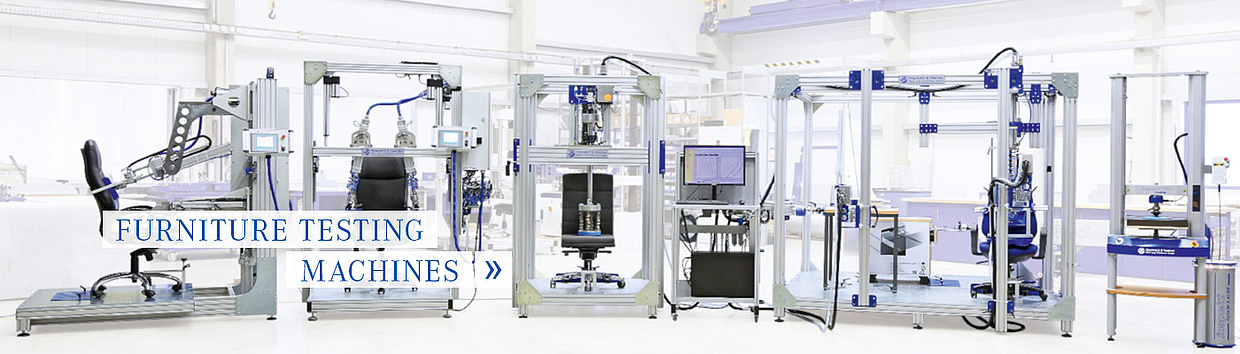

Furniture and component testing equipment

Furniture and components are exposed to a wide variety of stresses in daily use. At the same time, they must meet high demands in regard to safety, quality and durability. To ensure that furniture and components can meet these demands, testing of individual components and also the finished product is important. This applies to the development phase and just as much quality assurance in production. Last but not least, furniture and components must comply with the specification of numerous national and international standards or certifications (e.g. the GS symbol in Germany) to be able to succeed on the market. The Calmar furniture and component testing equipment from Hegewald & Peschke provides the right instruments to meet all these testing tasks.

Calmar works with pneumatic and electrical test axes in performing dynamic endurance tests, ageing and function tests. The unusual freedom in the arrangement of these test axes the system offers is reflected in its name. If necessary, Calmar features many freely movable arms – just like a calamary. In this manner, furniture and components can be subjected to widely differing loads, load accelerations and directions of stress. This allows close to reality simulation of the stresses the product must withstand in its intended use.

Hegewald & Peschke has developed a modular principle for the test rigs and test stands for furniture testing and component testing, which allows a configuration in 4 simple steps. Customer-specific requirements can be implemented flexibly and in accordance with standards.

Overview of modular system Calmar Pro furniture test fields

Overview of modular system Calmar One furniture test fields

For the operation of the test benches, two different control concepts are available for selection:

Calmar Pro - a software-based control concept which allows to carry out several independent test tasks

Calmar One - a PLC-based control concept, easy and comfortable to handle which allows a faster processing of the test task thanks to shortened cycle times.

Send an inquiry about component and furniture testing technology

![[Translate to englisch:] Prüfstand von Hegewald und Peschke für Tests an Sitz und Rückenlehne.](/fileadmin/_processed_/a/8/csm_Biegewechselbelastung-Sitzmoebel_eb18d4624a.jpg)

![[Translate to englisch:] Prüfstand Schubladenprüfung](/fileadmin/_processed_/2/d/csm_Schubladenpruefung_24ed00634a.jpg)

![[Translate to englisch:] Prüfstand Bettenprüfung Matratzenprüfung](/fileadmin/_processed_/9/e/csm_Bettenpruefung-Matratzenpruefung_af4862863c.jpg)

![[Translate to englisch:] Zubehör Kindermöbelprüfung](/fileadmin/_processed_/3/6/csm_Zubehoer-Moebelpruefung_b026c2b65b.jpg)