Search Results

Torsion testing device for tests according to DIN ISO 7800

Torsion testing device TW-500H

The TW-500H torsion testing device is optimally designed for wire testing according to DIN ISO 7800. The simple torsion test according to DIN ISO 7800 can be performed quickly and easily with the help of the user-friendly, intuitive operation via a touch panel.

Torsion testing device

Torsion testing machine T-200H

With the T-200H torsion tester, a maximum torque of 200Nm can be achieved at a rotational speed of up to 60 turns per minute.

Universal testing machine inspekt micro LC100N

Static-dynamic material testing machines up to 100N

The universal testing machine inspekt micro has been designed for a large number of challenging test tasks. Fields of application include, e.g. the semiconductor industry, the electronics industry or medical applications. The wide range of accessories of the Inspekt micro series and its special evaluation technology ensure quick, flexible and low-cost testing. The ergonomic workplace allows for easy clamping of micro specimens and components.

Testing technology for seats and seat rows in rail vehicles

Test rigs for functional tests, fatigue tests, durability tests

Various testing options specifically for testing railway seats:

- Tension test

- Compression test

- Swivel test

- Pendulum impact test

- Drop test

Electromotive linear axes

Electromotive linear axes for the testing of rotary doors, sliding doors, roller doors, filing cabinets and drawers

With electromotive linear axes (linear modules), a wide range of test setups can be realized simply, solidly and precisely.

Application:

- static, cyclic and dynamic loads

- endurance tests, functional tests, fatigue tests

- e.g. testing of hinged doors, sliding doors, roller doors, filing cabinets, drawers and hinges according to EN 14749 and EN 14074

- e.g. rolling test according to the standards BIFMA/ANSI X5.1, EN 1335-3 and ES 1038 with and without thresholds on seating furniture, containers and rolling tables

Automatic hardness tester – 500N

500N automatic hardness tester for circular blanks

Sample parameters

- Circular blanks Ø14 to Ø36 mm with edge heights of 1.0 to 3.0 mm

- Weights of the circular blanks from 1 g to 15 g

- Sample material ranging from homogeneous to multi-layer material compositions with electroplated coatings

- Sample surface of Al, Cu, Ni, Ag, Au, St with surface structures ranging from matt to high gloss

Double alternating bending test rig

Double test rig for chair testing - Calmar one

Carrying out seat and backrest tests, side-to-side and armrest tests according to EN 1335, EN 581-2, EN 1728, BIFMA X5.1, BIFMA X5.4, BIFMA X6.5, BS 5459

Torsion testing device

Torsion testing machine T-500H

With the torsion tester T-500H a maximum torque of 500Nm at a rotational speed of 25 turns per minute can be realized.

Mechanical specimen grips

Gripping, clamping, holding - from rough to fragile

Hegewald & Peschke offers a wide range of mechanical grips for tensile tests. This includes both from-fit and force-fit grips, each of which can be used for a wide range of materials, specimen shapes and temperature ranges.

Mechanical specimen grips at a glance:

- Vice grips

- Pincer grips

- Wedge type grips

- Screw type wedge action grips

- Specimen holders for shoulder, screw and thread head testing

Testing machine for torsion tests

Torsion testing machine 5000Nm

The torsion tester T-5000H is designed for single-axis torsion tests. A maximum torque of 5000Nm at a rotational speed of 2 revolutions per minute can be realized.

1D length measurement device "light"

digital measurement tool made of aluminium for lightweight rod-shaped workpieces, tubes, profiles, poles, bars, belts, cords, cuts…

- measuring length from 950 mm to 3,850 mm in a variety of graduations

- accuracy: ± (0,06mm + 0,02mm x L), L=measuring length in m

- very easy to use

Automated hardness tester for car and truck rims

Brinell hardness testing (HBT) according to DIN EN ISO 6506

The hardness tester for rims is an electromechanic special hardness tester, that is specialised for rim testing. The test frame divides in samples table, guidance device with load device followed from the test head.

Alternating bending test rig for seat and back rest

Alternating bending test rig for seating furniture - Calmar one

Performance of chair testing:

- seat/back rest load acc. to BIFMA X5.1, EN 581-2, EN 1335, EN 1728, BS 5459

Creep compressive test device for cardboard

Creep testing machine under weight-loading in a climate chamber

The device for the creep compressive test in a climate chamber is intended for the testing of corrugated cardboard under climatic influence and loading by weights. The testing machine can also be used as a tabletop unit outside of a climate chamber.

Pneumatic grips

Controlled clamping with compressed air - versatile and efficient

Pneumatic grips are used primarily for tensile tests in a load range of up to 20 kN and for testing specimens that are sensitive to clamping. They enable efficient material testing with convenient operation either via hand or foot switch.

Advantages of pneumatic grips:

- versatile application possibilities:

- suitable for testing fibers, foils, paper, textiles, plastics, strips, tapes, wires

- suitable for materials sensitive to clamping forces

- high efficiency for testing large quantities

- constant controllable clamping force over the whole test

- more cost-effective, lighter and smaller required space compared to hydraulic grips

1D length measurement device "heavy" - floor model

very robust measuring device made of steel, fixed on the floor

- measuring length: 4000 mm (others on request)

- for cross sections up to 230 x 1500 mm

- quick change system for measuring jaws

Universal test fields

Universal test fields for alternating bending tests on seating furniture, upholstery, and tables - Calmar pro

- testing of seat, seat back, arm rests and side to side test on seat and upholstery furniture as well as horizontal and vertical testing of tables in accordance to current standards, e.g. EN 1335-3, EN 581-2-3, EN1728, EN 527-3 and BIFMA X5.1

- integrated drop testing and testing of casters on seat furniture acc. to EN 1335, EN 68878, EN 1728, DIN 4551, DIN 4545, EN 581-2, BIFMA X5.1, refer to article 40-920-182

Hot hardness testing system

Determination of the Vickers hardness in the range 300°C to 1500°C

This hot hardness testing machine is used to determine the hardness of metallic and ceramic high temperature materials. It enables the determination of the Vickers hardness in vacuum in the temperature range of 300-1500°C and is intended for use in the materials testing laboratory.

Device for torsion testing

Rotary module device 800Nm

Rotary module device 800Nm for forming friction tests.

Furniture test rig

Testing of chairs and tables according to DIN EN 1728 and DIN EN 1730

The variable and modular test field of the Calmar series consists of a central control unit and five force/displacement-controlled electromechanical test axes. It can be used to carry out cyclical service life tests as well as fatigue tests on components and furniture.

Displacement test rig for tables

Displacement test rig for vertical and horizontal testing of tables and desks - Calmar pro

- Displacement test rig for vertical and horizontal testing of tables according to EN527-3, EN581-2-3, EN1730, BIFMA X5.1 load or load/position controlle

- 4 test axes for horizontal table testing, 1 test axis for vertical table testingr

- the test axes each have their own controllers assembled in the immediate vicinity, which are operated from a PC via CAN-bus and work synchronised

Test stand for torsion testing

Torsion test stand inspekt T3500

The potential field of application of this testing system comprises mechanical stress tests for determining technological and physical material properties of square ended specimens.

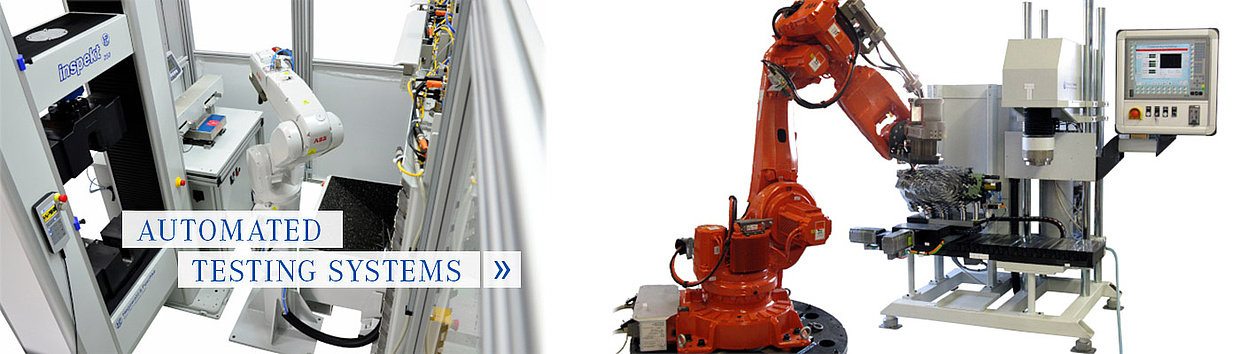

Brinell hardness testing station for components and finished products

Hardness testing in combination with robot technology

Hegewald & Peschke MPT GmbH has developed a robot-based hardness testing station which can be used to fully automatically test the Brinell hardness of components and finished products. The fully automated hardness testing centre gives new impetus to industrial quality assurance as it offers high test speeds and evaluation independent of the user as well as automatic registration of the test results. If required, the entire production series can be thoroughly tested without the results having to be manually evaluated.

Universal testing machine inspekt solo

Material testing machines up to 2.5 kN

The universal testing machine inspekt solo is a very lightweight testing machine, which has been designed for simple standard tests or customer-specific, more challenging tests...

Rotational impact tester

for impact tests

The rotational impact tester is used for impact tests. These highly dynamic tensile tests with a long linear test path are applied, for example, in the testing of fibre composites and technical textiles.

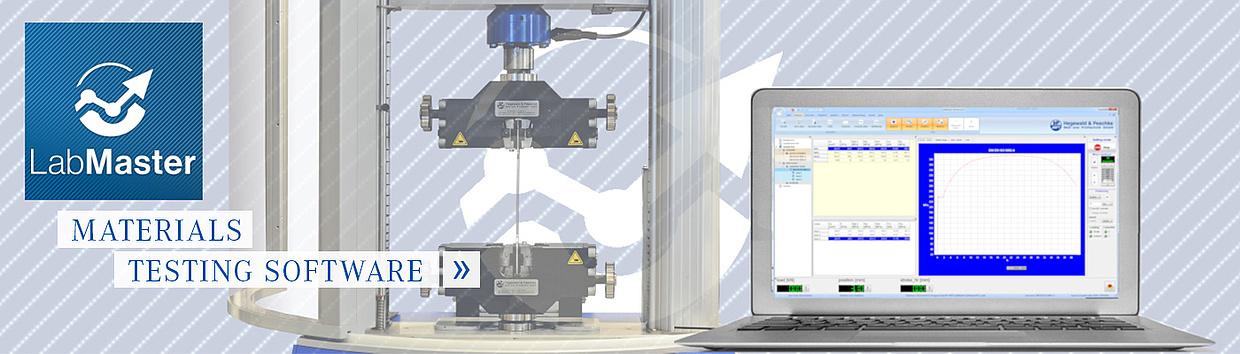

Universal testing machine inspekt duo

Material testing machines up to 10 kN

The inspekt duo is a versatile two-spindle tensile testing machine for test loads of 5 to 10 kN. It is a further development of the inspekt table blue series from Hegewald & Peschke.

The inspekt duo machine series is ergonomically designed. Characteristic features include the large base plate, which allows the connection of peripheral devices such as extensometers, as well as the coupling of a tool tray and the equipment with protective doors. This guarantees use in harsh production environments as well as in sterile laboratories. The LabMaster materials testing software is available for fast and reliable evaluation of test results.

Portal hardness testing device with ball caster table

Rockwell hardness testing at large and heavy elements

The testing portal is used for the hardness testing based on the Rockwell method HRC according to DIN EN ISO 6508 at large and heavy elements. The machine frame is built as a portal with a clear width of 1360mm and a clear height of 1000mm above the ball caster table, so that components up to a maximum width of about 1200mm and a maximum height of about 900mm can be crossed and tested. The minimal height of the specimen is 100mm.

Creep bending test machine for cardboard

Creep test under weight-loading in a climate chamber

The device for the creep bending test in a climate chamber is intended for the testing of corrugated cardboard under climatic influence and loading by weights. The testing machine can also be used as a tabletop unit outside of a climate chamber.

Electromechanical test axes

Test axes for furniture testing, component testing and material testing

Electromechanical test axes can be used to perform fatigue tests, operational strength tests, functional tests and also static tensile tests, compression tests, bending tests and peel tests. The field of application of these test axes is very versatile and covers the areas of furniture testing, component testing and material testing.

High temperature testing system up to 1,800°C

Special testing machine inspekt S 50 kN

The high temperature testing system is based on the universal testing machine series inspekt. The inspekt S 50kN high-temperature testing machine from Hegewald & Peschke can be used to determine the mechanical properties of metallic and ceramic materials as well as metalloceramic composites. These are used, for example, as heat shields in space technology or as heat-insulating building materials.

Universal testing machine inspekt blue

Material testing machines up to 30 kN

The inspekt blue material testing machines were designed for standard and routine tests. These universal testing machines are used, among other things, in quality assurance and are characterised by a particularly attractive price/performance ratio. The inspekt blue is suitable for tensile tests, compression tests, peel tests and bending tests on various materials. In combination with the ergonomic design and the new brushless drive concept, a safe and fast measurement is guaranteed with simplest operation both in the rough production environment and in the sterile laboratory area.

Small load hardness tester HP30S

Small load hardness tester from HV 0,005 to HV 50

The small load hardness testers HP30S was developed for the usage of a range from HV 0,005 up to HV 50 and comes with a digital hardness measurement display. The hardness tester can be eqipped with several software- and picture evaluation systems and be completed to a fully automated hardness test system.

Pneumatic test axes

Pneumatic test axes for different applications

- Pneumatic cylinder (Festo), round cylinder with tie rods

- Load-controlled, or load and position-controlled actuators (pneumatic test axes) with a 5 kN load cell and 20 mm clamping adapter for easy connection and exchange of pressure pieces

- Test loads of 1500 N / 2500 N / 4500 N (depending on the piston diameter)...

HPO 250

Vickers-Brinell hardness tester – HPO 250

- Vickers 5-10-15-20-30-40-50-60-100-120

- Brinell 15.625 - 31.25 - 62.5 - 187.5 - 250

Testing rig for fittings

Testing rig for the testing of fittings, hinges and folding mechanisms

- frame is mounted ca. 200 mm high (on vibration-absorbing feet which can be fixed to the floor)

- frame dimensions ca. 1,6 m x 1,8 m, in the specimen area 1,2 m x 1,8 m, with grid hole system 150 mm x 150mm M10

- motor-driven height-adjustable frame construction for the electromotive pivoting unit; installation in existing test rig

Linear module

Linear axis for testing cabinet doors, drawers and rollers

With this testing system, endurance tests can be carried out on revolving, sliding, horizontally moving roller and folding doors, cabinets and drawers in furniture pieces and castors of various types of furniture. The linear unit of the test stand is controlled and operated from the PC via a special testing machine controller.

Test stand for ladder testing in acc. to EN131

Testing of ladders

Force-controlled Calmar Pro test rig for vertical ladder tests, 2 cylinders for vertical testing according to EN 131, with testing and evaluation software CalMaster.

The pneumatic test axes each have their own controllers assembled in the immediate vicinity, which are operated from a PC via CAN-bus and work synchronised. Pressurized air and power is supplied to the test axis from the central supply terminal.

Universal hardness tester HPuniversal 250/750/3000

Universal hardness tester Vickers-Brinell-Rockwell-Knoop

The universal hardness tester HPuniversal is available as 250, 750 and 3000 kp device with a electromotive load application. Contrary to the normally load application by weights, all standardised test loads can be realised in the case of HPuniversal and its design.

Hydraulic grips

The safe push-button grip - convenient and unbelievably strong

Fast and slide-safe tensile tests according to national and international standards, on worked and non-worked flat and round test pieces of metallic and nonmetallic materials of all tensile strengths...

Brinell hardness testing station for components and finished products

Hardness testing in combination with robot technology

Hegewald & Peschke MPT GmbH has developed a robot-based hardness testing station which can be used to fully automatically test the Brinell hardness of components and finished products. The fully automated hardness testing centre gives new impetus to industrial quality assurance as it offers high test speeds and evaluation independent of the user as well as automatic registration of the test results. If required, the entire production series can be thoroughly tested without the results having to be manually evaluated.

Hardness Testing Software HardWin XL

Universal hardness testing software with modular automation systems

Universal hardness testing software with modular automation systems for:

- micro hardness tester HMV-2

- small load hardness tester HP5 - 30

- universal hardness tester HP250 - 3000

- modernisations

Test stand for mattresses and cushion frames

Combined test stand for durability and hardness tests on mattresses and cushion frames

- Entire testing according to EN 1957 in one test stand possible

- No falsification of measured values because no rearrangements or transport of the mattresses and cushion frames between the durability test and the measurement of the hardness values H and HS are necessary

- The system can also be used for tests according to ASTM F1566

Application Digital Scale

Milling machines, Turning lathes, grinding machines, drilling equipment, cutting machines

Magnescale® characterizes a compact Design, which makes an installation under close space conditions possible without limiting the motion travel of the machine. Depending upon requirements can be selected from a various product range suitably to your application.

Wire testing machine

Reverse bend testing machine 180° for wire samples

The facility is used for bending fatigue tests according to DIN 51211 and ISO7801 on wires with diameters of 0.3 - 10.0mm. The wire samples are bent with a 90° angle to the left and to the right...

Device for shock tests

Device for impact tests according to EN 61730-2

This machine allows shock tests for solar modules according to the standard EN 61730-2. The modules have to be fixed vertically on a transport trolley, which has been equipped with an appropriate support for fixation on the frame of the testing device.

Friction test stand

Friction test stand for examination of pin - cylinder pairs under climate influence

This test stand is used for examining cylinder – pin pairs in the range of sparse wear. The total wear is limited to 2.5 mm of which 1.5 mm.

Mechanical creep behaviour testing equipment

Mechanical creep behaviour testing equipment for leather samples

Load test stand with 5 load stations, respective maximum permissible load 200N by applying of maximally 4 50N-plates, enterprise by pneumatic circuit.

Fully-automated metal tensile test

Automated testing system with universal testing machine and robot

The automated test centre from Hegewald & Peschke offers high test speeds, operator-independent evaluation and automatic recording of test results. The core of the system is a universal testing machine of the type Inspekt...

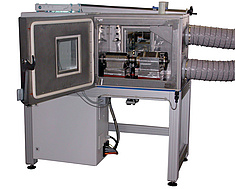

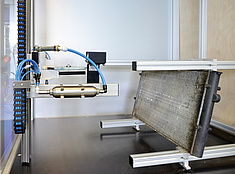

Stone impact tester

Test stand for stone impact tests

This stone chip tester can be used to test large components in particular, such as car radiators.

The test stand is tightly clad on all sides and can be opened from two sides. The firing device can only be operated when the door is closed.