Hegewald & Peschke develops and manufactures individual testing machines for testing unusual components and finished products. When developing special solutions, customers benefit from the proven and mature basic design of the Inspekt series. With its modular basic design, the Inspekt series allows changes to the load frame geometry. In this way, customised inspection systems for solving individual inspection tasks quickly become reality, even when implementing very detailed customer requests.

High temperature testing system up to 1,800°C

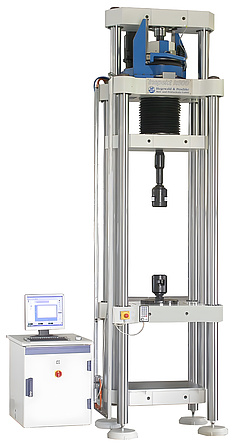

Special testing machine inspekt S 50 kN

The high temperature testing system is based on the universal testing machine series inspekt. The inspekt S 50kN high-temperature testing machine from Hegewald & Peschke can be used to determine the mechanical properties of metallic and ceramic materials as well as metalloceramic composites. These are used, for example, as heat shields in space technology or as heat-insulating building materials.

Calibration machine for three load cells

Testing machine 10 kN and 50 kN for calibration purposes

Universal testing machine inspekt table 10 kN or inspekt table 50 kN as calibration machine, equipped with three load cells. The testing machine is designed for testing and calibrating load cells in different force ranges.

Determination of the abrasion and friction properties on deep-drawn sheets

Special testing machines for strip tensile tests, friction tests and draw-bead tests

- Branch: Automotive industry

This testing machine allows to determining the abrasion and friction properties on deep-drawn sheets. Those sheets are used e.g. for engine bonnets, car wings, doors or pillars. The corresponding test procedure is the draw-bead-test.

Nominal ring stiffness testing of glass fibre-reinforced plastic pipes

Special testing machine inspekt S-XL 600 kN & special testing machine inspekt SH 500 kN

- Branch: plastics industry

Piping systems made of spun glass fibre reinforced polyester resins are mainly used for drinking water and waste water pipes and in irrigation and drainage systems. The pipe diameter can vary between 150 mm and 4200 mm. As the pipes are exposed to high pressure loads during installation, determining the mechanical properties is of central importance. This is done by testing the ring stiffness. Ring stiffness describes the strength behaviour of plastic pipes. Characteristic values are the crown compressive strength according to DIN EN 1228 as well as the compressive and circumferential elongation. All values are determined in both the circumferential and longitudinal directions.

Hegewald & Peschke offers two machines for this test.

Testing insulation materials

Universal testing machine inspekt S 20kN with three test areas

- Branch: plastics industry

Life without thermal insulation materials is inconceivable nowadays. In addition to typical material properties, key mechanical parameters determined of insulation materials also include tensile strength, expansion and compressive resistance and deformation behaviour...

Horizontal tensile testing of cables, wires, chains, etc.

Universal testing machine inspekt H-L 600kN with horizontal test area

- Branch: electrical industry

The universal testing machine inspekt H-L 600kN was developed as a horizontal material testing system for testing products with high strengths and measurement lengths, such as chains, cables, wires or finished products with extensive installation lengths...

Hot stamping of microstructures

Precision forming machine inspekt 600kN P.U.M.A.

- Branch: research

Within the scope of a research project with the Fraunhofer Institute IWU in Chemnitz, the fundamental feasibility of a technology for the hot stamping of non-metallic materials in the high temperature range was examined...

Testing heavy current isolators

Universal testing machine inspekt SA-4S 600kN with central loading spindle

- Branch: electrical industry

Isolators are used in a broad range of energy-related applications. They are subjected to a wide spectrum of electrical and mechanical influences under real ambient conditions during operation...

Testing flooring elements

Universal testing machine inspekt S Vario 30/50kN with mobile loading axle

- Branch: wood and plastics industry

Flooring elements and their support systems are subjected to extreme mechanical loading in the form of compressive and bending forces...

Testing foams

Universal testing machine inspekt S 5kN with central loading

- Branch: plastics industry

Soft elastic foams are primarily used for damping and insulation. Almost all plastics are suitable for foaming...

Calibration of force reference standards

Reference standard measurement machine inspekt K 600kN

- Branch: Verification laboratories, calibration services

Load cells, which are used for example in classic material testing machines, must be checked periodically for their measuring accuracy with reference force standards...

Universal shaft testing in the automotive industry

Universal testing machine inspekt S-L 250kN in horizontal configuration

- branch: automotive industry

Automotive universal shafts and drive trains are subject to considerable compressive and tensile mechanical loading during use...

Calibration machine

Universal testing machine Inspekt 2500 kN

Force reference standard measuring machine up to 2500 kN for calibrations of reference force standards and reference transducers.

Calibration machine 50 kN

Testing machine inspekt KBNM 50 kN for calibration purposes

Calibration of load cells/force sensors/force transducers

Nominal ring stiffness testing of plastic pipes

Universal testing machine inspekt S 50kN with a working area width of 750mm

- Branch: plastics industry

The nominal ring stiffness characterises the strength behaviour of plastic pipes in the construction, electrical and water/waste water industries and is subject to European standards.

Static puncture tests and bending tests on glass

Glass testing machine inspekt S 50 kN

- Branch: glass industry

With the Inspekt S 50kN, stamp compression tests can be carried out on glass according to ISO 614 and bending tests according to DIN EN 1288-3 up to a maximum load of 50 kN.

Two-axis special testing machine inspekt V100kN/H1kN

Test on moments of pivot bearings under load

- Branch: Aircraft industry

Universal testing machine in special design with two axes - one vertical and one horizontal test axis: For the determination of torques of different joints under loads up to 100kN.

Component testing machine

Special universal testing machine inspekt S 300kN

This component testing machine has a test chamber height of 3500 mm and a test chamber width of 1680 mm, so it has been specially designed for testing larger components.