Applications

On this page you will find a selection of sample applications for our testing machines. If you are looking for testing solutions for a specific industry or material, you can also use our filter search:

Search by industry and/or material.

Tensile test on metal according to DIN EN ISO 6892-1 up to 100 kN

Universal testing machine inspekt table 100 kN

- Industry: Metal and steel industry

In the metal tensile test, a clamped specimen is loaded with increasing tensile force F and deformed by an extension ΔL until it finally breaks. Important characteristic values such as the tensile strength, the yield or elongation limit and the elongation at break are determined, which are crucial for the quality assurance of materials and components.

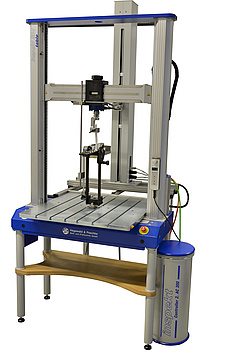

Tensile test on plastics according to DIN EN ISO 527-1

Universal testing machine inspekt duo 10 kN

- Industry: Plastics industry

The tensile test according to ISO 527-1 can be used to determine key mechanical properties of plastics such as tensile strength, yield strength and modulus of elasticity.

Testing machine for component tests on fuel cells

Component testing for electromobility

Fuel cells have the potential to fundamentally change the way we generate and use energy. They offer an efficient and environmentally friendly way of generating energy by converting hydrogen and oxygen directly into electrical energy and water without producing harmful emissions.

Testing machine for battery cell testing

Universal testing machine for component testing in the electrical industry

Battery cells are the crucial component of electric cars. In everyday use, they are exposed to a wide range of electrochemical, thermal and mechanical stresses. In order to avoid hazards and ensure the quality, functionality and durability of the battery cells, its components are tested in complex test procedures.

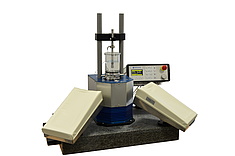

Determination of ring flexibility on thermoplastic pipes according to EN ISO 13968

Apex pressure testing machines of the inspekt series

The mechanical properties of thermoplastic pipes are of great importance for their possible applications in various branches of industry. EN ISO 13968 specifies the test methods for determining the ring flexibility of pipes to ensure that the materials can withstand the requirements of bending stresses. According to this standard, the following can be tested with apex pressure testing machines from Hegewald & Peschke.

Compression test on packaging (cartons/boxes) according to EN ISO 2234

Compression testing machine inspekt table 20 kN

Compression tests in accordance with DIN EN ISO 2234 are carried out on cardboard boxes to test the stacking behaviour, among other things. The strength of the packages is determined and the protection that the packaging offers its contents is assessed.

Metal tensile test according to DIN EN ISO 6892-1

Universal testing machine inspekt 1200 kN

- Branch: Metal and steel industry

The metal tensile test according to ISO 6892-1 is an integral part of quality assurance, especially for further processed materials and materials or components.

Testing of charging technology for electromobility

Test systems for electrical components

For the charging technology required in electromobility, Hegewald & Peschke has suitable universal testing machines from the small inspekt solo 2.5 kN to the robust inspekt table 100 kN in its range.

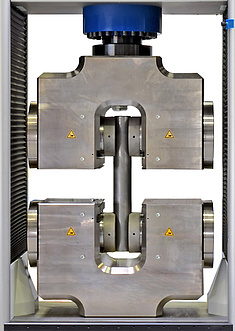

Testing of force sensors, force transducers and load cells according to DIN EN ISO 376

Universal testing machine inspekt KBNM 50 kN

Force sensors and load cells are used in many areas of application. For example, they contribute to the safety of machinery and equipment or are used for experiments to determine tensile and compressive forces.

To ensure their measuring accuracy, they are regularly calibrated by calibration offices. An inspekt calibration machine for reference transducers in the measuring range up to 50 kN can be used for this purpose.The 4-column design of the new calibration machine results in a high rigidity of the load frame and a resulting high measuring accuracy.

Testing of sandwich elements according to DIN EN 14509

Testing machine for bending test, compression test and tensile test according to DIN EN 14509

With the universal testing machine inspekt duo 10 kN, bending tests as well as compression tests and tensile tests according to DIN EN 14509 can be performed.

Length measurement on precision steel tubes

Length measuring machine "light" for quality assurance at pipe manufacturers

- Industry: Metal industry

Measuring the tube length of seamless and welded tubes made of steel and stainless steel is an important step in the quality assurance of these products. Length measuring devices from Hegewald & Peschke are used by various manufacturers of tubes.

Creep rupture tests on 3D-printed plastic foams

Universal Testing Machine inspekt duo

- Industry: Additive Manufacturing, Plastics Industry

For research and further development of the properties of 3D-printed plastic foams, a universal testing machine inspekt duo is used on which, in addition to simple compression tests, creep tests are also carried out at room temperature.

Tensile testing machine for metal tensile test on wire ropes

Universal testing machine inspekt 400 kN with hydraulic grips and video extensometer

The testing system is specially adapted to the testing of wire ropes. It includes a tensile testing machine with a maximum load of 400 kN, hydraulic grips and video extensometers for optical strain measurement.

Testing the actuating force of wire strippers

Testing machine for component testing

Wire strippers can be used to safely, quickly and reliably remove insulation from electrical wires of various thicknesses. To ensure a high level of operating comfort when using the wire strippers, the actuating force that the operator must apply should not be too great. When testing this force, a defined maximum value must not be exceeded.

Testins of springs

Testing machines for spring testing

Selection of testing machines and testing technology for material and component testing on springs:

Material testing on plastics and composites

Testing of plastics

A presentation on the testing process, standards, testing machine requirements and application examples for testing plastics and composites.

Bending test on wood materials

Universal testing machine inspekt table 50 kN

4-point bending test according to EN 789 and shear test according to EN 789

Tensile test on steel pipes

Universal testing machines inspekt 400 up to 2500 kN

Tensile testing on pipes or pipe strip specimens with universal testing machines of the inspekt series in a load range from 400 kN to 2500 kN

Testing of nonwovens and textiles

Universal testing machine inspekt solo-M 2,5 kN

Determination of tensile strength and tear resistance according to DIN EN ISO 13934-1 and DIN EN ISO 9073-4

Bending test on ceramic according to ASTM C674

Universal testing machine inspekt solo 2,5 kN

3-point bending tests with measuring probe according to ASTM C674 to characterize the properties of the ceramics both before and after the firing process

Testing the shear forces of contact elements

Universal testing machine inspekt table blue 20 kN with shear device

Shear tests are used to determine whether the solder contacts between the switching contact and the component can withstand the high stresses to which they are subjected in practice, often with many millions of switching cycles. For this purpose, the component to be tested is clamped in a specially developed shearing device and subjected to a steadily increasing shearing force until the switching contact shears off.

Testing of electrical switches and buttons

Universal testing machine inspekt table blue 5 kN

By means of special devices it is possible to check the amount of force and path for actuating and releasing the buttons and for actuating the switches.

Tensile test and Brinell hardness testing on screws

Universal testing machine inspekt table 100 kN

The inspekt table 100 kN is used in this application in the field of research and development on metals as a tensile testing machine for tensile tests on flat and round specimens, connection and thread specimens as well as shoulder head specimens.

Testing of pipe segments

Universal testing machine inspekt table 50kN

Testing of shoulder samples from pipe cross-sections of water pipes, gas pipes, connecting elements in tension and bending according to DVS2203, also tensile tests on copper strands (cable strands with connecting element). Testing system consisting of universal testing machine inspekt table 50kN, wedge grips 50kN, 3-point bending bench and LabMaster.

Tensile test on cables and strands

Universal testing machine Inspekt table blue 20kN

Test system for tensile force tests on cables, cables with plugs, ferrules and cable lugs, which are installed in control cabinets. The testing system consists of the universal testing machine Inspekt table blue 20 kN with two load cells (20 kN and 3 kN), one TH170-50 wrap-around grips and a pair of wedge grips with clamping jaws for flat samples with saw tooth profile.

Testing on disc springs

Universal testing machine inspekt 100kN

For this application the universal testing machine Inspekt 100kN is used as a clutch spring testing machine. For this purpose it is equipped with a suitable testing device for disc springs.

Testing of paper and cardboard

Universal testing machine Inspekt 20 kN

With this testing system, consisting of the testing machine Inspekt 20 kN and a climate chamber, a wide variety of tests of paper and cardboard as well as corrugated board and tissue paper are possible. For example, tests for the packaging industry on the bending and buckling stiffness of cardboard or creep tests to observe the behavior of paper and cardboard under the influence of humidity, temperature and time can be carried out.

Breaking strength of hypodermic needles

Universal testing machine inspekt duo 10 kN

Universal testing machine inspekt duo 10kN to determine the breaking and bending strength of hypodermic needles in the field of medical technology.

Gas spring testing

Universal testing machine inspekt solo-L 1 kN

Universal testing machine inspekt solo 1 kN in L-design with increased testing speed of 3000mm/min for testing gas pressure dampers.

Drum peel test on sandwich specimen - Testing of composites

Universal testing machine inspekt table 20 kN

Test system for drum peel test on sandwich composites materials according to DIN EN 2243-3 and ASTM 1781.

Spring testing machines - Testing of springs

Universal testing machine inspekt table 20 kN

The spring testing system consists of a universal testing machine inspekt table 20kN, compression plates 20 kN with exchangeable mandrel for spring testing, two load cells (500 N and 20 kN) and the testing software LabMaster with the module stiffness correction.

Testing of protective gloves via puncture resistance test

Universal testing machine inspekt duo up to 10 kN

A universal testing machine inspekt duo up to 10 kN is used. It is equipped with a special device for pressure tests on gloves or glove cut-outs made of polyethylene or latex and material testing software LabMaster.

Calibration machine for external force sensors

Calibration with universal testing machines from Hegewald & Peschke

Beside the application for classical tensile, compression and bending tests universal testing machines from the Hegewald & Peschke Meß- und Prüftechnik GmbH can also be used as calibration machines. For the application of the universal testing machines as calibration machines the Hegewald & Peschke MPT GmbH has developed the module "calibration" in its in-house material testing software LabMaster.

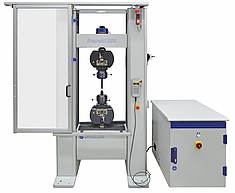

Fatigue testing of metals - VHCF test

Universal testing machine Inspekt 20 kN with VHCF device

- Branch: Metal and Steel industry

The growing demand for efficient lightweight construction in various fields of application demands the use of modern materials with ever increasing numbers of load cycles. Research and development, and especially testing technology, present a number of new challenges.

Determination of tensile and flexural strength of metals and non-metals

Universal testing machine Inspekt 600kN with lateral test room 200kN

- Branch: Metal and Steel Industry

The testing system includes a universal testing machine Inspekt 600kN with a lateral testing area and a 3-point bending bench 250kN as well as a hydraulic clamping tool 600kN and a fully automatic long distance extension measuring device MFL 300-B.

Determination of fracture mechanics

Universal testing machine Inspekt 100 kN

- Branch: Metal and steel branch

Components may already show cracks or similar defects during the manufacturing process. Using static tests on deeply cracked specimens to determine fracture toughness, manufacturers and users can prevent material failure through controlled crack growth, monitoring and - if necessary - maintenance/repair.

Testing of sandwich panels

Universal testing machine Inspekt 150 kN

- Branch: Research and Development, Textile Industry, Plastics Industry

With this testing system consisting of a universal testing machine Inspekt 150 kN, a 3-point bending bench and further testing devices, various standard-compliant tests on sandwich composites can be carried out.

Testing of electronic components

Universal testing machine Inspekt table 20kN

- Industry sector: Electrical Industry

With this extended universal testing machine Inspekt table 20 kN various components can be tested.

Testing of metal components

Universal testing machine Inspekt 100 kN

- Industry sector: Metal Industry

The testing machine is equipped with a hydraulic clamping tool, a rear protective wall and a MFX200 long-stroke extensometer.

Testing of reinforcing steel

Universal testing machine Inspekt 400 kN

- Branch: Building Industry, Metal and Steel Industry

This universal testing machine Inspekt with a maximum test load of 400 kN can be used for bending and tensile tests on reinforcing steel.

Testing of screws according to standard

Universal testing machine inspekt 250 kN

- Branch: Metal and Steel Industry

This universal testing machine inspekt 250 kN can be used for testing screws.

Testing of textile materials and geotextiles

Universal testing machine inspekt 100 kN

- Branch: plastics industry

Textile structures are extremely versatile. Geotextiles, for example, are often used in the construction industry. Depending on the wide range of possible applications, a wide variety of tests can be carried out on textile materials.

Testing of connection elements

Universal testing machine Inspekt table blue 5 kN

This universal testing machine Inspekt table 5 kN is equipped with a screw clamping tool, pliers or scissors clamping tool as well as a T-slot plate and further extensive accessories for clamping in order to test interface products.

Determination of the shear strength of brake linings

Universal testing machine Inspekt table 250 kN

- Branch: automotive industry

With this universal testing machine Inspekt table 250 kN brake linings can be tested for shear strength. For this purpose, this testing machine has been equipped with a shearing device, a hydraulic unit and an industrial safety door...

Testing of metals and alloys in research

Universal testing machine Inspekt 250 kN

- Branch: education and research

This universal testing machine Inspekt 250 kN is used in basic university research in the field of production technology. For this purpose, the universal testing machine is equipped with a hydraulic clamping device which enables optimum clamping of these short tensile specimens...

Pipe testing

Apex pressure testing machines

- Branch: plastics industry

Determination of the ring stiffness on pipes

When testing the ring stiffness, differently sized pipe sections are tested depending on the underlying standard and the application the pipes are designed for.

In addition to ring stiffness, ring flexibility, minimum compressive strength and compression strength can also be determined.

Determination of the mechanical properties of solar panels

Universal testing machine inspekt solo 2.5 kN

- Branch: Solar industry

This universal testing machine inspekt solo 2.5 kN allows together with a special testing device to test in production the mechanical properties of solar modules, e.g. thin film solar modules...

Testing of flat tensile samples for the automotive industry

Universal testing machine inspekt 250 kN

- Branch: Automotive industry

With this universal testing machine inspekt 250kN flat tensile samples of aluminium, stainless steel and a variety of deep-drawn sheets can be tested, that are used in the automotive manufacturing...

Testing of chains

Universal testing machine inspekt 600kN + 300kN with lateral test chamber

- Branch: Metal and steel industry

The universal testing machine inspekt 600kN with lateral test chamber serves to test the strength of chains. The main test chamber is provided for the tensile tests on chains...

Determination of mechanical properties on components for the automotive and aviation industry

Universal testing machine inspekt table 20kN

- Branch: Automotive industry, aviation and aerospace industry

This testing machine can be used for tensile, compression and peel tests. In comparison to the standard design, the test room is enlarged, which enables the testing of slightly bigger components as well...

Component testing on steel and aluminium for the automotive industry

Universal testing machine inspekt 250kN

- Branch: Automotive industry

The application area of the universal testing machine inspekt 250kN includes metal tensile tests on round aluminium specimen complying with DIN EN ISO 6892 as well as special component tests...

Determination of mechanical properties on aluminium

Universal testing machine inspekt table 50kN

- Branch: Metal and steel industry

Especially standard tensile tests according to DIN EN ISO 6892-1 shall be performed with the testing machine. Tensile testing for metallic materials at room temperature is defined with this standard...

Metal tensile tests on standardised test specimen

Universal testing machine inspekt 250kN

- Branch: Metal and steel industry

This universal testing machine inspekt 250kN can be employed as material testing machine for pressure and tensile tests on standardised samples, in particular on metallic materials. The testing machine features...

Metal tensile tests on sheet samples and tension/pesssure tests on components for car seats

Universal testing machine Inspekt table 100kN

- Branch: Automotive industry

The testing machine inspekt 100kN features a wider test space in order to test also larger scale components. Furthermore, it is equipped with a work safety door of a new design...

Static-dynamic testing of dental implants

Micro testing device inspekt micro LC 100N

- Branch: Medical industry

The micro testing device Inspekt LC 100N can record material fatigue caused by mechanical stress and ambient conditions. The permanent load test is simulated with maximum load application of 100N as well as 50Hz for alternating loads...

Determination of mechanical properties on CFRP samples

Universal testing machine Inspekt 250kN with temperature chamber and video extensometer

- Branch: Automotive industry, aviation and aerospace industry, plastics industry

Carbon fibre reinforced plastics (CFRP), commonly referred to as carbon, are manufactured by embedding carbon fibres as reinforcement into a plastic matrix. This structure ensures high strength and rigidity accompanied by low weight; the material is therefore used, for example, in aeronautics, vehicle construction or for sports equipment...

Reliable material inspection at high temperatures

Universal testing machine inspekt 100kN with a second testing room and a furnace applicable to either test room

- Branch: aviation and aerospace

Manufacturers of metal components in the aviation and aerospace sector that are often relevant to safety set great store in individually configurable material testing that is not susceptible to malfunction. Especially testing at elevated temperatures is of great importance for the quality assurance of the respective final product...

Testing of implant materials and laboratory instruments

Universal testing machine Inspekt table blue 20kN with squeezing device

- Industry: Medical technology

Innovative biomaterials, such as bone cements, bone implants, as well as substitute materials make an important contribution to improving the quality of life of affected patients. Before these products can be used in the context of a medical treatment, they have to pass strict quality controls...

Tensile tests on the components of vehicle seats

Universal testing machine inspekt 100kN, extended by 550mm, with an external load cell

- Branch: automotive engineering

To reduce the risk of injury in automobile accidents, especially safety relevant components of vehicle seats are tested using the inspekt 100kN special testing machine in terms of their material quality and stability...

Testing Equipment for the determination of adhesion forces

Universal testing machine inspekt mini 3kN

- Branch: automotive engineering

A modern automobile is made up of up to 10,000 individual components, including numerous small and micro components. The Inspekt mini 3kN universal testing machine enables tensile and pressure tests on especially sensitive and sometimes heavily stressed small components like side windows at cars with an inspection fixture for detention force determination of splicing tapes...

Tensile, compression and bending tests on GRP pipe systems

Universal testing machine inspekt 100kN with a lateral test room 50kN

- Branch: plastics industry

GRP pipes are often part of a critical network in civil engineering, for energy suppliers or in other industrial plants. Often, not only they do transport relatively harmless substances and environmentally friendly liquids, but also chemicals, contaminated cooling or heating water, crude oil and similar. To prevent leaks – and thus contamination of the soil and ground water – plastic pipes must meet high material requirements...

Compression and bending testing on styrofoam samples with automatic feeding system

Universal testing machine inspekt table 5kN

- Branch: plastics industry

Styrofoam is especially light and requires an extremely precise testing procedure that can manage large quantities: as part of continuous production, for instance...

Tensile, compression and bending tests on ceramic components

Universal testing machine inspekt table 50kN with a special device for ceramic specimens

- Branch: automotive industry

Since the invention of the spark plug in 1901, ceramic components have gained a secure place in vehicle manufacturing. They are built into a wide variety of components and make an active contribution towards vehicle safety, environmental impact and vehicle comfort. Typical areas of use include, for example, catalytic converters, sensors and lighting technology, particle filters, and much more...

Stress tests with pneumatic indentation

Universal testing machine inspekt mini 3kN with electro-pneumatic specimen marking and ejection unit

- Branch: aviation industry

The Inspekt mini 3 kN universal testing machine conducts stress tests on so-called "firing pins" and is equipped with electro-pneumatic sample marking and pneumatic sample ejection for practical fixation...

Tensile testing of metals and plastics at various temperatures

Universal testing machine 100kN with lateral test room 50kN and temperature chamber

- Branch: metal and plastics industry

The universal testing machine inspekt 100kN with lateral test room 50kN was constructed for the tensile testing of metals and plastics at high and low temperatures...

High temperature metal tensile testing at temperatures up to 900°C using fourtube furnaces

Universal testing machine inspekt 250kN, extended

- Branch: metal and steel industry

Due to long waiting periods for preheating, warm tensile tests are often very time consuming – and thus expensive. The Inspekt 205 kN universal testing machine offers remedies in two ways: reliable test results and shorter test duration...

Toughness testing (KIC) on steels in the low temperature range

Universal testing machine inspekt 400kN

- Branch: steel industry

The universal testing machine inspekt 400kN was developed for material testing in the low temperature range...

Fracturing force of the safety belt, safety belt tightener and safety belt buckle combination

Universal testing machine inspekt 100kN, extended version

- Branche: automotive industry

The inspekt 100kN universal testing machine determines the fracturing force of the safety belt, safety belt tightener and safety belt buckle combination with a nominal load of up to 100kN...

Metal tensile testing in accordance to DIN EN ISO 6892-2

Universal testing machine inspekt 250kN for tensile testing at elevated temperatures

- Branch: metal industry, research and education

In metal tensile tests carried out in accordance with DIN EN ISO 6892-2, the warm stretching limit of a material is determined. Hegewald & Peschke MPT GmbH has equipped the Inspekt 250kN universal testing machine with an extended testing chamber as well as a hinged 3-zone furnace (up to 900°C) for this...

Suche nach Branche und Material